Most people know that a CNC Router can cut wood. But many don’t have an idea that a CNC router can cut metals that are stronger than basic wood-like aluminum. For cutting aluminum usually people tend to opt for high-end milling machines.

A cnc router aluminum on the other hand has a spindle that can operate at a higher speed than a typical milling machine. They are used for cutting wood materials using rounding edges, slot cutting, or lettering.

But many people don’t know that CNC Routers can also cut aluminum if they follow a few simple tips.

Tips that help in cutting Aluminum

1. Taking time

When compared to a milling machine a cnc router aluminum will have a low removal rate. As the metal that is being cut will also be larger than the mill, it is okay to take some time for the process.

2. Using proper Bit

When working with aluminum it is better to avoid cobalt and HSS cutters. It is advised to use 2 to 3 flute carbide endmills as they will allow a high spindle speed rate on the router.

3. Using cutters with small diameters

To get high feed rates and smooth cuts it is better to avoid ½” endmills and opt for ¼ or even smaller ones.

4. Clearing the chips

When the chips are immediately cleared that can save the router from getting broken. Using an airblast to automatically remove the chips is advisable.

5. Cut depths and slotting should be observed

If the cutting depth is more, the slot of the cutter travels in and it will be harder to remove the chips from the bottom of the hole.

6. Always lubricate

In removing chips along with air blast set up a mist oiler. Lubricating will keep the cutting edges sharp along with making cutting easy and even there will be a high success rate.

If there is no lubrication, the chips get welded into the cutter because of the chemical affinity that aluminum has with the cutter which will be very dangerous.

7. Avoid slow feed rate

If the feed rate is slowed there is a risk of rubbing the tool instead of cutting it. As the spindle speed is high when compared to the miller, this can be risky for cnc router aluminum users.

8. Give importance to safety

It is important to be safe when working with any sort of metal using CNC or any drilling machine. It is essential to wear eye protection and always make sure to clamp the metal that is being drilled.

More Information about CNC Routers

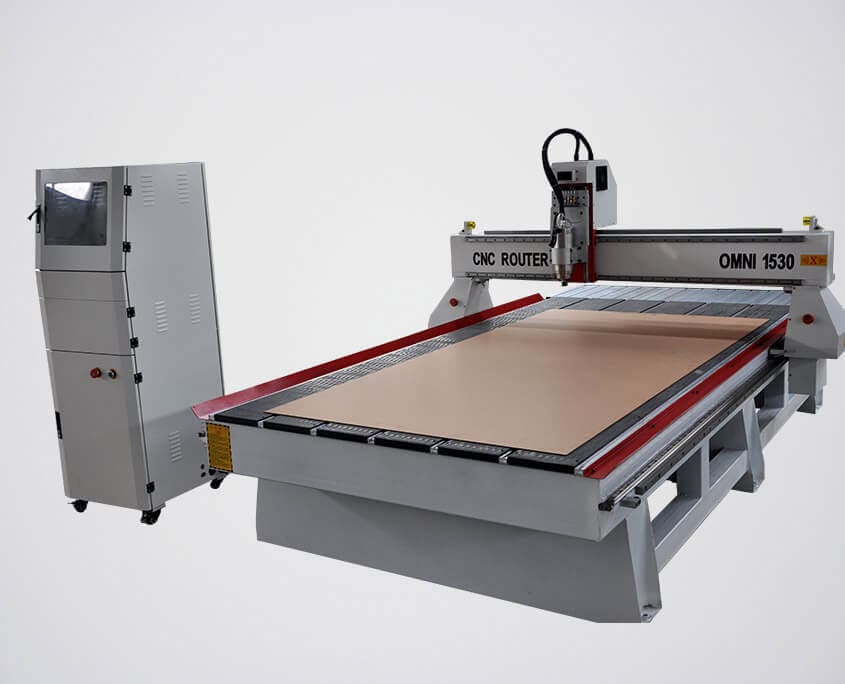

● CNC routers are automatic three-dimensional cutting machines.

● There is a possibility of minimal waste and there will be fewer errors with cnc router aluminum.

CNC Routers available in market

1. Sain-Smart 3018- Prover

2. Cenoz 3018 Pro

3. Bobs CNC Evolution 3

4. Gowe

5. Millright power XL

Conclusion:

CNC routers can cut aluminum when correct feeds and speeds are used and when the pitfalls are avoided. Many CNC Routers fail to cut aluminum because of the lack of lubrication.

The best cnc router aluminum is a good quality carbide end mill that has 3 or less than 3 flutes.